Case studies

We love getting our advice and solving our customer’s problems. See our approach.

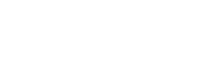

Ergonomics at a Good Price

One of the Clients had a good idea for a new product. However, it was hard to predict whether the product will sell well. In addition, in the case of the traditional production, the implementation costs would be difficult to recover, if the product would require significant amendments after the initial tests.

Flexible, Dynamic Solutions

The client has assumed that approximately 10,000 units per year, within the period of three years will be produced. However, he was not entirely sure if the project would succeed. He also had to, for reasons related to the market situation, be ready with the first batch of 1,000 pieces within 45 days after the order has been placed.

Non-standard Plastic Case

The client liked the standard plastic case however, because of the visual identity of the company it had to be made in an unusual color. The change required time, but yet the client wanted to quickly release the pilot batch on the market.

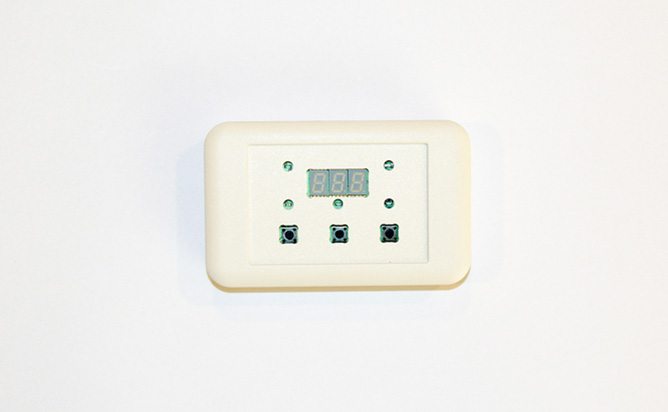

Milling, printing and self-clinching

The client needed a solid and handy housing for his device, an internet connection quality tester. This device was to be used by service employees to measure the quality of the internet connection.

complete solution

machining, assembling

complete solution

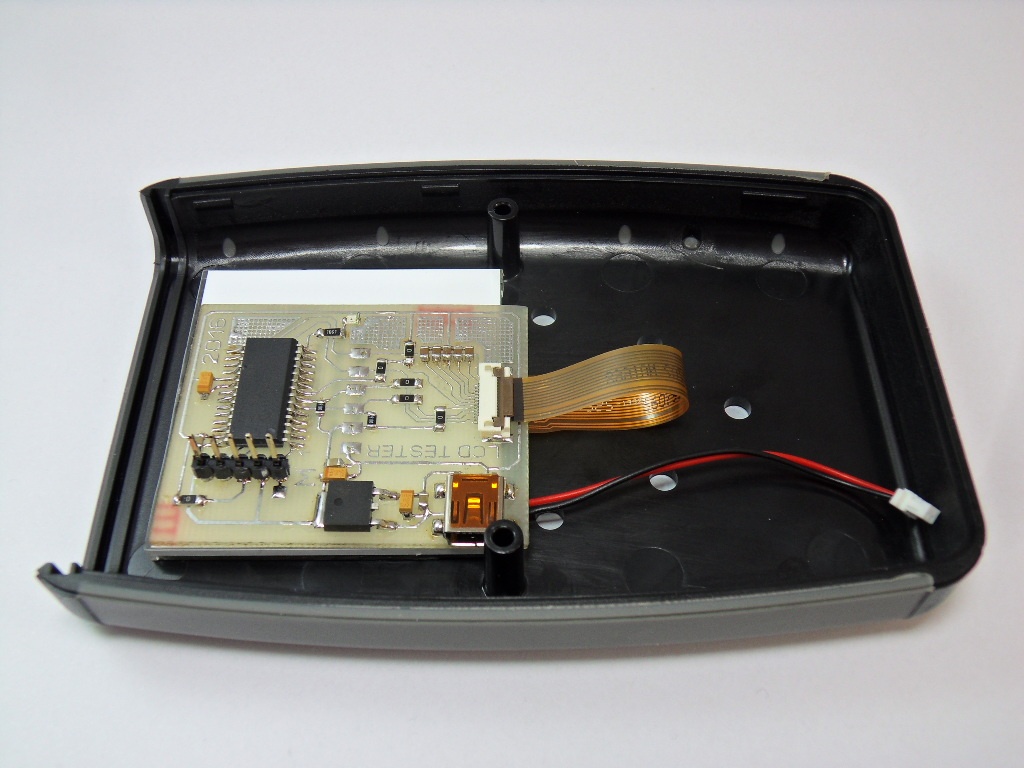

keypad, final assembling

"reverse" keypad

keypad with keys on rear side

modifications

direct printing, machining

Interested by our stories? So, let us do all the hard work and give us a call or fill in our online contact form.

Tomasz Kamiński

Tomasz.Kaminski@lcel.com.pl

+48 22 569 53 07

Marcin Gapisz

Marcin.Gapisz@lcel.com.pl

+48 22 569 53 11

Marek Ćwikła

Marek.Cwikla@lcel.com.pl

+48 735 963 166