The SIT methodology supported us to organize thinking about innovation. We already know that innovations are not created by chance, but are a deliberate and planned process. In this article you can read about multiplication technique and application of this innovation in the LC Elektronik.

SIT gives us the tools which are the five techniques. First, we took subtraction – we discussed it

What multiplication is?

The idea of multiplication is copying of already existing element, and then modifying it, even if at the beginning it seems to be unnecessary. Not always more is better, but in this case, it is true. Good examples of using this technique are:

- the use of two lenses in new smartphones, one wide-angle lens

and one telephoto lens, - multiplication of the number of blades in razors,

- increasing the number of tweezers and creating an epilator,

- adding two smaller wheels to training bikes for children to make them more stable and help children learn.

You admit that it is simple and brilliant at the same time?

Know how: Application of multiplication technique in LC Elektronik

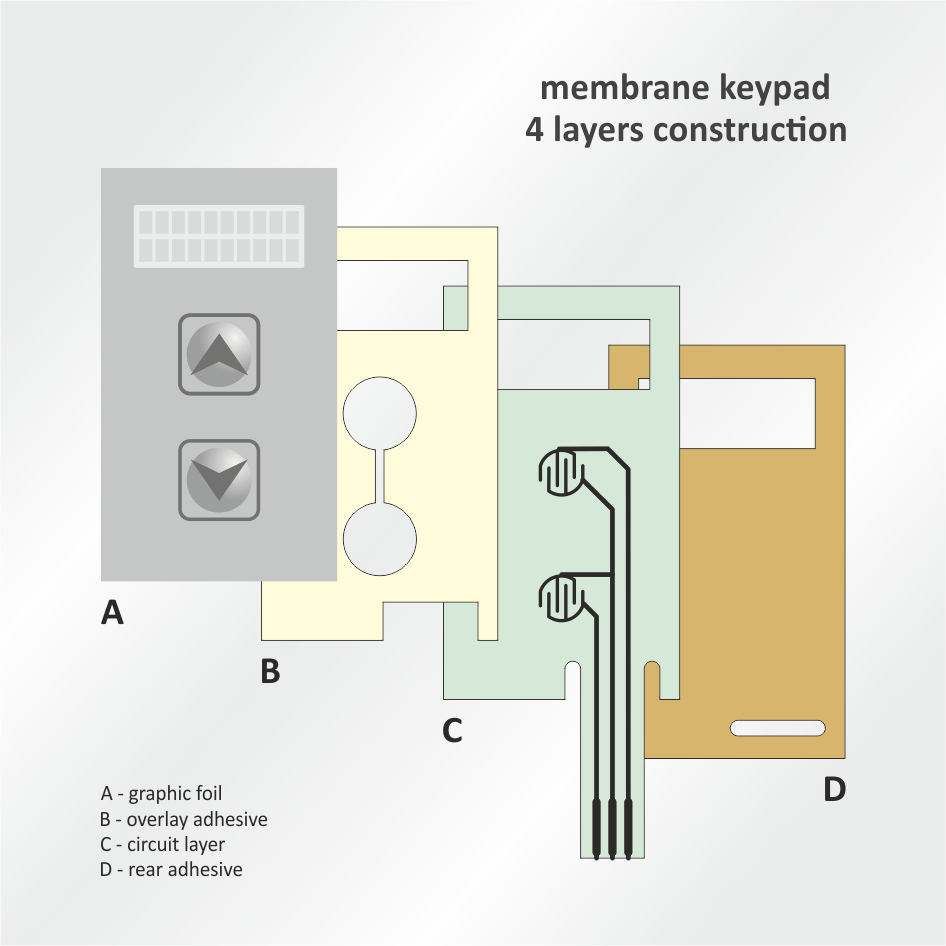

Membrane keypad – 6W type construction

For over 30 years of our practice, we constantly try to improve our products to make them more and more reliable. At the beginning, in the production of membrane keypads, we used a four-layer construction. It consisted of:

- Graphic foil printed at the bottom side

- Overlay adhesive/spacer

- Circuit layer (with paths based on silver colloids)

- Rear adhesive.

This construction was an economical solution. Very thin – only 4 layers. But during a longer operation, it had one basic disadvantage: after some time, the ink printed on the graphic overlay began to peel off, the printed silver was damaged and this not only had a negative influence on the aesthetics but mainly ink chips got into the circuit layer and short-circuits occurred. All mentioned injuries resulted in malfunctioning of the device. In addition, the slightly pressed top layer began to deform. So 4W technology keypad did not meet our requirements.

We began to conduct research and looking for a new reliable solution.

This is how the idea of 6W founded – a membrane keypad containing six layers minimum.

We added two layers and the keypad structure contained the following elements:

- Graphic foil

- Overlay adhesive/spacer

- Metal dome layer

- Spacer

- Circuit layer (with path based on silver colloids)

- Rear adhesive

An example of a 6W keypad structure

Such a simple modification, consisting of adding two layers, made the keypad work without any problems and at the moment we guarantee a minimum of 1 million switches for each key.

The 6W construction ensures:

- No deformation on the

graphic overlay. - Non-spraying paint.

- Perfect protection of the circuit layer – it is protected by four layers, not two, which significantly affects its protection.

Higher operational strength of the entire keypad.- Very good click effect of a polyester membrane – important when you can’t use a metal dome and similar effect is needed.

The 6W structure slightly increases the thickness of the keypad, therefore for applications requiring a thinner construction, we simply choose materials with a smaller thickness.

The benefits of using a six-layer construction make it applicable to all types of keypads, i.e. standard versions and with a metal or polyester dome.

Thanks to the multiplication of layers in the keypad, our products are reliable, work for many years, even in difficult conditions or in other climatic zones.

As you can see, the multiplication technique worked and helped us find

the simplest and most effective solution.