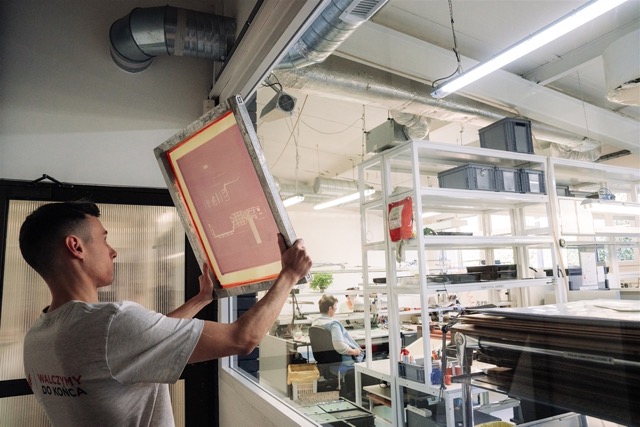

YOUR PRINTED ELECTRONICS PARTNER – FROM SOLUTION TO PRODUCT

Meet growing market expectations with printed electronics from LC ELEKTRONIK:

- quality components increase the value of your products,

- accelerated implementation process reduces time to market,

- we support you from concept to volume production.

Printed electronics – our products

Contact printed foil

Create modern and intuitive user interfaces with our contact printed films. They ensure the reliability and long life of your devices.

Flexible printed layouts

Give your designs new freedom with flexible printed layouts. Ideal for devices with custom shapes and requirements.

Sensors and capacitive sensors

Enhance the functionality of your products with our precision sensors. They offer reliable performance in the most demanding applications.

Printed heating mats

Ensure comfort and energy efficiency with our heating mats. They are easy to integrate and perfect for a variety of applications.

Medical sensor printing

We offer medical sensor printing essential for modern diagnostic and monitoring devices. We use biocompatible materials and precision printing technologies to create sensors that monitor vital signs such as heart rate, temperature and physical activity. Benefits: Patient safety We use materials that comply with medical standards. This translates into a lower risk of allergic reactions and irritation, which directly improves patient comfort and safety, especially during long-term monitoring. High sensitivity and accuracy of sensors Extremely sensitive sensors not only ensure rapid detection of even the smallest changes in vital signs, but also increase the reliability of diagnostic devices. This allows doctors to make better clinical decisions based on reliable data. Flexibility and comfort Thin and flexible sensors are comfortable for the user.

Variable resistance pads

Discover new ways to control and interact with your devices with variable resistance pads. We customize them to your specific needs.

Printed electronics – our services

Technical analysis and idea verification

Every breakthrough product starts with an idea. Our experts carefully analyse your concept, identifying potential challenges and proposing optimal solutions. This minimizes risk and maximizes the chances of success. By working with us, you gain confidence that your project is technically feasible and complies with the latest industry standards.

R&D

We support you in developing new products and technologies, offering full R&D support. Together, we can push the boundaries of what’s possible with innovations that will set your company apart in the marketplace. Our R&D team is ready to work with you at every stage of your project, from concept to implementation.

Printing conductive paths on flexible polyester substrates

We support you in developing new products and technologies with full R&D support. Together we can push the boundaries of what’s possible with innovations that will differentiate your company in the marketplace. Our R&D team is ready to collaborate at every stage of your project, from concept to implementation. Benefits:

Variable resistance contact field printing

We specialize in printing contact fields with adjustable resistance, which allows us to create interactive panels and touch sensors with varying sensitivity. Our technology makes it possible to precisely control the resistance in individual areas, which is crucial in applications such as game controllers, sensor mats and user interfaces. Benefits Executing ideas without compromise Our solutions enable the design of electronic circuits that can be adapted to the most unusual and complex shapes, opening the door to innovative applications in a wide range of industries – from consumer electronics to medicine. This allows customers to realize their unique ideas without compromising on form or function. Durability and lower maintenance costs Thanks to advanced printing technologies, our conductive pathways retain their properties even under harsh conditions such as frequent bending, humidity and temperature fluctuations. This means long life and stable performance, resulting in higher equipment reliability and lower maintenance costs. Optimizing weight and space Our conductive paths on flexible substrates are not only extremely thin and lightweight, which is crucial for applications requiring minimization of component weight and thickness. This makes our products ideal for mobile devices, wearables and in applications where every millimeter and gram matters.

Medical sensor printing

We offer printing of medical sensors essential for modern diagnostic and monitoring devices. We use biocompatible materials and precision printing technologies to create sensors that monitor vital signs such as heart rate, temperature and physical activity.

Benefits

Patient safety

We use materials that comply with medical standards. This translates into a lower risk of allergic reactions and irritation, which directly improves patient comfort and safety, especially during long-term monitoring.

High sensitivity and accuracy of sensors

Extremely sensitive sensors not only ensure rapid detection of even the smallest changes in vital signs, but also increase the reliability of diagnostic devices. This allows doctors to make better clinical decisions based on reliable data.

Flexibility and comfort

Thin and flexible sensors are comfortable for the user.

Printed resistance heaters

We offer printed heating mats and resistive heaters for various industries, from automotive to consumer electronics. Our heaters feature even heat distribution and the ability to customise heating power to meet specific needs.

Benefits

Energy efficiency

Precise resistance control ensures optimum energy consumption, resulting in significant savings and more efficient operation of heating systems.

Customisation

We can design our resistive heaters in any shape and size, allowing full integration into various projects – from automotive to consumer electronics.

Durability

We use high-quality materials to ensure long life and resistance to wear and tear, even in harsh operating conditions.

Even heat distribution

Our heating mats provide stable and even heat emission, eliminating the problem of hot spots and ensuring consistent comfort.

Flexible applications

Can be used in various industries, from vehicle heating systems to consumer electronics components, making our solutions versatile and easy to implement.

Printing with transparent conductive varnishes – an alternative to ITO films.

We offer printing with transparent conductive varnishes as an alternative to traditional ITO (indium tin oxide) films. Our solutions allow you to create transparent electrodes and conductive layers in touch panels, displays or intelligent windows.

Benefits

High transparency

Our conductive coatings provide excellent transparency, making them ideal for touch screens, displays and smart windows, where aesthetics and functionality must go hand in hand.

Substrate flexibility

The ability to print on flexible substrates gives you an advantage over traditional ITO films, which are rigid and limit the design of next-generation devices.

Cost optimisation

Our solutions reduce production costs by using less expensive materials, such as indium, used in ITO films, making conductive varnish printing more economical.

Better material availability

Compared to ITO films, transparent conductive varnishes are based on more readily available materials, eliminating the risk of raw material shortages.

Increase profitability with LC Elektronik printed electronics

Technology companies are facing complex challenges. Rising manufacturing costs and uncertainty in the supply chain can threaten the profitability of your business. If you’re looking for a manufacturer that can not only provide you with high-quality printed electronics components but also help you optimise your processes and innovate, LC Elektronik is the perfect choice. With our 100% quality control and EU supply stability, you will gain confidence in your strategic planning. Our technical advice will allow you to introduce new products faster than your competitors, translating into increased profits and a stronger market position for your company.

Benefits for your company:

-

Improved profitability through efficient solutions in printed electronics.

-

Strengthened market position through the introduction of innovative products.

-

Operational security through a stable supply chain and elimination of unforeseen downtime.

Optimize purchasing processes with printed electronics

Purchasers’ daily challenges include unpredictable prices and delivery times, making budget planning difficult. Too many supplier choices complicate the decision-making process, and a lack of technical expertise can make it challenging to evaluate bids.

LC Elektronik is the answer if you’re looking for a printed electronics partner that will simplify your purchasing processes and ensure reliability. We offer honesty and transparency in communication and terms of cooperation. A dedicated account manager supports you at every stage of your order, and our repeatable production guarantees consistent quality and on-time delivery. Our technical advice makes it easier to understand the technical aspects of products, resulting in more effective purchasing decisions.

Benefits for your company:

-

Simplify the purchasing process with clear rules and expert support.

-

Increased efficiency by reducing the time spent searching for and evaluating suppliers.

-

Guarantee repeatable production through proven processes and stable cooperation with a trusted partner.

Open yourself to innovation with printed electronics

As a designer, you may face limitations due to lack of access to documentation and 3D models or problems integrating components from different sources. Limited experience in other industries can inhibit your innovation, and a complicated certification process makes it difficult to meet standards.

LC Elektronik offers solutions to help you overcome these challenges. We provide complete technical documentation with drawings and 3D models and technology advice in selecting the best-printed electronics solutions and materials. With physical prototyping, you can test and verify your designs, and the selection of raw materials and technologies will help you meet standards and certifications.

Benefits for your company:

-

Design flexibility through access to the latest technologies.

-

Acceleration of the implementation process through rapid prototyping and testing.

-

Support in certification through compliance of our solutions with international standards (ISO 9001:2015, REACH and RoHS, SA8000 (SAI), ISO 45001)

Effective project management with printed electronics

With tight project deadlines, lack of knowledge of available technologies and communication issues with suppliers, project management can be a challenge.

LC Elektronik offers solutions to make your job easier and help you achieve your project goals. We offer quick turnaround on projects with express deadlines and a dedicated project manager to ensure efficient communication. Our honesty and transparency eliminate misunderstandings, and technical advice supports you in choosing the best solutions.

Benefits for your company:

-

Confidence and predictability: an OTIF (On Time In Full) rate of 95%, with an average turnaround time on production of 18 working days.

-

A team of dedicated professionals – 2 technical advisors, 3 support engineers and 4 customer service people.

-

Attention to your satisfaction – monitoring the quality of customer service.

Frequently Asked Questions (FAQ)

What are the minimum order quantities?

We adapt to your needs, regardless of the size of the project.

Do you offer product design support from scratch?

Yes, our team of experts can help you at every stage—from concept to design to production.

How long does the process take from inquiry to production and order fulfillment?

The response time to an inquiry is a maximum of 24 hours. Turnaround time depends on the scale and complexity of the project, but we always strive to deliver products in the shortest possible time.

Can I count on confidentiality and protection of intellectual property?

Absolutely yes. We respect the privacy and intellectual property of our clients. We can sign an NDA agreement upon request.

What is the complaint process in case of a defective product?

Our priority is your satisfaction. In the event of a complaint, we take corrective action immediately, in accordance with our quality procedures.

Do you have quality certifications, what standards are you compliant with?

ISO 9001:2015

We are ISO 9001:2015 certified, which confirms our commitment to maintaining the highest quality standards in every aspect of our business.

REACH and RoHS compliance

Our products comply with REACH Regulation (EC) 1907/2006 and RoHS Directive 2 (EU) 2011/65/EU. We do not supply any products, chemicals or mixtures containing critical or hazardous substances by these regulations.

Social responsibility and occupational safety

We operate by SA8000 (SAI) and ISO 45001 guidelines, demonstrating our commitment to an ethical approach to business and concern for the safety and health of our employees.

Materials and responsible sources of raw materials:

Our products do not contain cobalt or mica as a raw material, ingredient or additive.

For products containing tantalum, tin, tungsten or gold (3TG), raw materials are sourced from sources specified by OECD guidelines, ensuring responsible sourcing of materials.

How do you help builders with component topography?

Often, builders send us a preliminary layout of the elements in a design. Our team of experts reviews these designs for:

The feasibility of routing the paths in the electrical system

We verify that the designed layout allows for efficient and reliable routing of paths, which is crucial for the device’s functionality.

Preserving safety margins

We ensure appropriate distances are maintained between components and from the edges of the keypad or circuit board. This minimizes the risk of short circuits and other electrical problems.

Putting the design into practice:

We verify that the design does not contain difficult-to-fabricate elements, such as overly fine printing or complex graphics, which can increase the risk of rejection during production and raise costs. In this way, we optimize the design together, resulting in a higher quality final product, reduced production costs and shorter time to market.

Do you make a prototype for clients? On what terms?

Yes, we always make a prototype for the customer. This key stage allows us to verify that what we have agreed with the customer actually meets his expectations.

The prototype is a form of assurance for both us and the customer, ensuring that the product is as intended before series production begins.

Prototyping is always included as a separate item in the quote. It consists of two components:

Implementation costs

Include the development of production and implementation documentation and preparation of connectors, templates and printing meshes.

As part of this stage, we also purchase dedicated materials, create unique ink formulas and prepare CAD/CAM programs for machines, stamping dies, dies and assembly templates.

Prototype consists of producing the first small batch of up to 10 pieces of the product. This allows us to practically test the product and make any adjustments before total production begins.

Making a prototype ensures that the final product will meet all quality and functional requirements, which translates into customer satisfaction and efficiency of the production process.

How do you select raw materials? What kind of raw materials do you work with?

At LC Elektronik, we pay great attention to the selection of raw materials to ensure consistency, repeatability, and availability of our components. We have a stable base of proven suppliers, which we periodically evaluate, verifying their products, quality of service and timely delivery. As a result, we guarantee the high quality and reliability of our products.

We work with three categories of raw materials:

Basic raw materials

These are the key components regularly used in our production. It must pass rigorous quality tests to add a new raw material to this category. We conduct tests in prototype series and in larger production batches. We subject these raw materials to aging tests to verify their durability over time. Furthermore, we also perform endurance tests, such as simulations of several hundred thousand button presses, to ensure they meet the highest quality standards.

Alternative raw materials

These spare components can be used when needed. Although they have not fully passed our standard tests, they are available as an option in emergencies or when the specifics of an order require it. This allows us flexibility in deliveries and minimizes the risk of delays.

Design raw materials

These are specialized components ordered for a specific order or customer project. We select them in close cooperation with the customer to meet the unique technical and functional requirements of a particular project. This allows us to provide perfectly tailored solutions.

If you have additional questions about our raw materials or the selection process, please feel free to contact our team. We will be happy to provide detailed information and help you choose the best solutions for your project.

What are the payment terms?

Normally, we handle the first three transactions on the basis of prepayment. Once the cooperation is established, we offer flexible payment terms to suit your needs.

Can I visit your company and see the manufacturing plant and production process?

Of course! You are welcome to visit our headquarters and see our processes. Please contact us in advance to arrange a visit.

Maciej Flis

Business Development Manager

maciej.flis@lcelektronik.com

LC Elektronik is a company that places great emphasis on the quality of its implementations, but also takes an equally qualitative approach to relationships with customers and its own employees. LC Elektronik is also constantly looking for opportunities to improve its way of doing things, adapting to and even exceeding growing market demands and customer expectations. Over the years, the owners have managed to build a solid and good place to work.

Don't wait – take the first step towards innovation!

Paweł Czabak – CEO

pawel.czabak@lcelektronik.com

LC Elektronik belongs to:

LC Elektronik Sp. z o.o. Sp. k.

Pułkowa 58

01-969 Warszawa

NIP: 1182177838

KRS: 0000742155