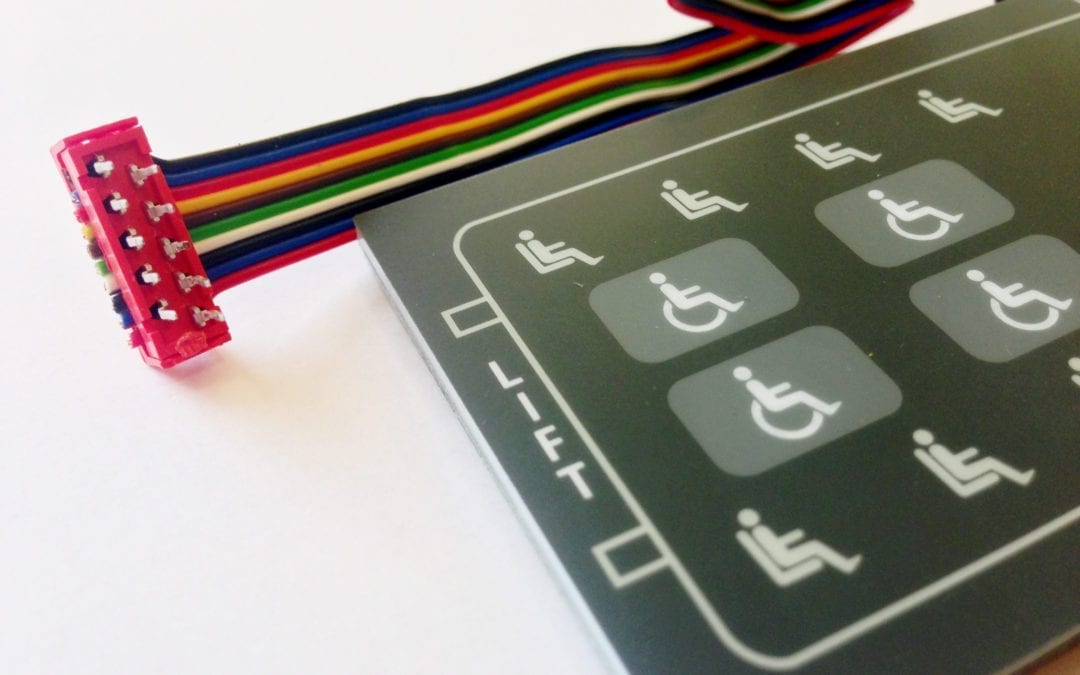

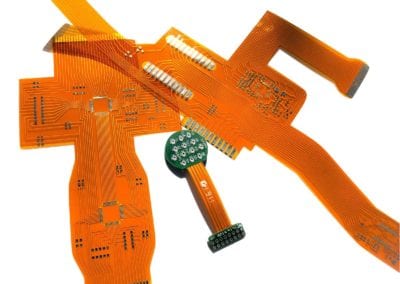

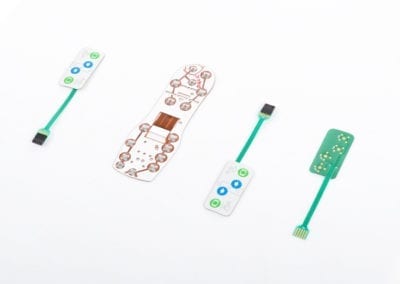

In PCB and Cu-Flex keypad’s construction, flexible or rigid printed circuit board (PCB) is base.

What is the Cu-Flex and PCB?

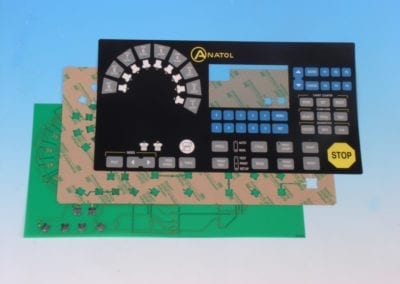

The printed circuit board (PCB) consists of an insulating material on which paths and solder pads are located. It is made with an etching technique. Glass-epoxy laminate or a composite material are coated with copper. Electrical connections are printed and then further processed. The structure can consist of one, two or more layers. The components are assembled on the PCB in two ways: THT (through hole technology) or SMT (surface mount technology). The plate can be the keypad’s back panel at the same time.

The flexible printed circuit (Cu-Flex) is made of a dielectric material, usually a polyimide or polyester film, on which electroplated copper conductive tracks are printed, insulated on both sides. The flexibility of the circuit depends on the material used and the number of layers. Thickness usually oscillates between 12 and 125 μm. The thicker the circumference, the stiffer it is, which affects the smaller deformation.

The advantage of Cu-Flex is its small thickness, easy adaptation of the tile to the shape of the enclosure.

What distinguishes printed circuit keypads?

The use of a printed circuit in the construction of the keypad allows placing beside contact fields and other electronic components. Additionally, there is a possibility of making gilding of contact elements and the use of gold domes, which allows to significantly improve the quality and reliability of the keypad. This solution is recommended for keypads that work in extremely difficult conditions.

Application

The printed circuit keypads find a wide application among electronic devices, in the telecommunications, medical, military, IT and usable equipment sectors.

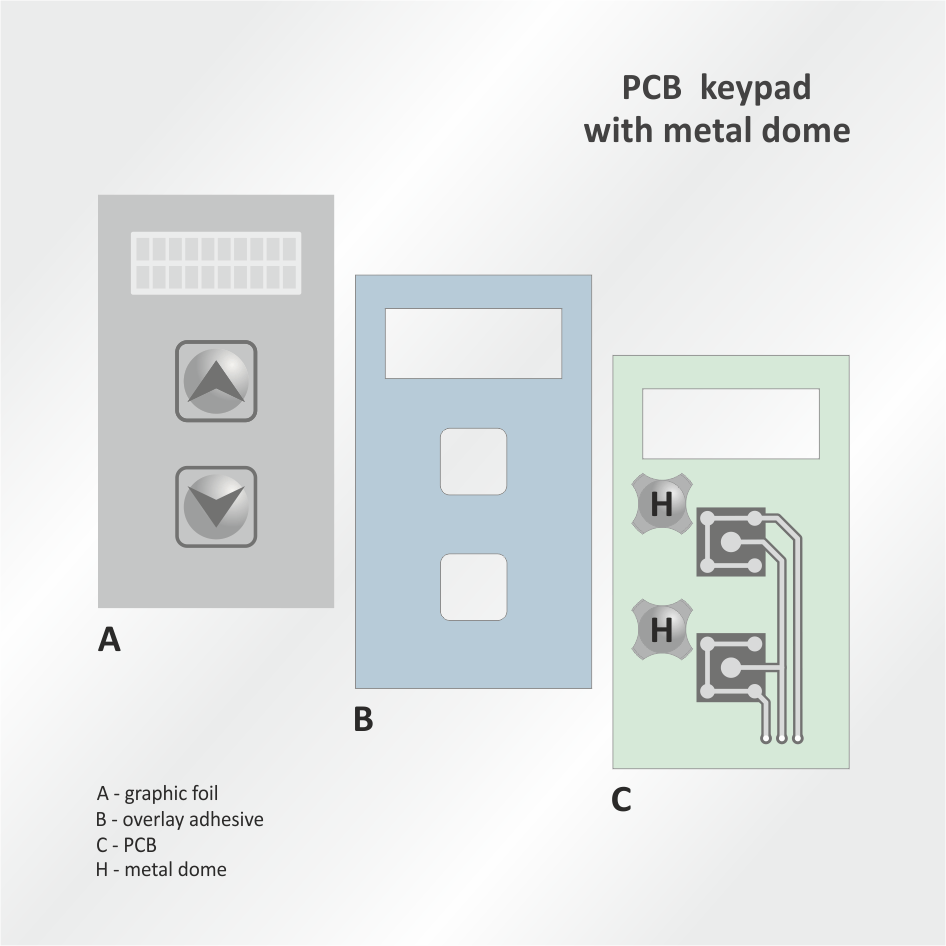

Exemplary construction of PCB keypad

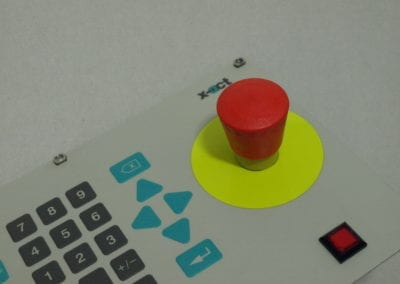

embossed keypad with a metal dome on the PCB

Technical information about PCB and Cu-Flex keypads

| Printed circuit | Rigid / PCB | Flexible / CU-flex | |

| Supporting material | glass-epoxy laminate or composite material | polyimide or polyester | |

| Paths material | copper | ||

| Gold plating | yes | ||

| SMD elements: LED connectors other electronic components |

yes yes yes |

||

| Plug in bag | yes | ||

| Number of layers | single-, double-, multiple-layer | 1-50 | |

| Number, shape, thickness of paths | any | ||

| Minimum distance between paths | 0,076 mm | ||

| Type of laminate | – single sided – double sided |

||

| Type of front | – graphic overlay – silicon cover |

||

| Keys | – flat – pressed – with metal domes |

||

| Windows shielding | yes | ||

| Electromagnetic protection of display windows | yes | ||

| Backlighting | LED one-colored and two-colored |

||

| Holes | – any number – any shape – through |

||

| Surface finishing | – glossy – antiglare – hard coated |

||

| Windows for LED elements | – transparent – colored filters |

||

| Connectors | – wires directly soldered to PCBs, 2,54 mm pitch – ZIF connectors and WR-FFC, 1 mm, 0,5 mm pitch – ribbon cables with IDC MiniModule, pseudo 1,27 mm pitch system – bundle of cables with Autocom WR-WTB, 2,54 mm pitch |

– ZIF or Non-ZIF, from 0,5 to 2,54 mm pitch – possibility of extension the tail by DWFC technology |

|

Design

| Color | any |

| Shape | any |

| – screen printing – digital print |