Digital printing is a revolution in printing technology on an industrial scale. Often displaces the traditional screen printing method, because it gives interesting effects, allows to use of an infinite color palette and tonal transitions. The production process of digital printing is also much less complicated and cheaper than the screen printing method. That’s why we use digital printing technology more and more often, in creating decorative foils for membrane keyboards and for direct printing on electronics enclosures as well.

What is the difference between digital printing and screen printing?

What is screen printing?

Screen printing consists of squeezing paint through a mesh that has exposed meshes in the desired pattern. Therefore, it is necessary to print each color in turn. The order of applying colors, trapping and margins are also important. It should be noted that printing very fine text through the sieve is cumbersome, because the holes can become clogged with inks, and consequently the printed elements are incomplete. However, the unquestionable advantage is the sharpness of printing and the fact that uniformly colored surfaces are free from the effect of swimming colors.

What is digital printing?

Digital printing is about applying dots by the printer head, a plotter or other machine in CMYK colors, i.e. cyan, magenta, yellow, black. These dots are normally not noticeable, are visible only under the microscope. The size of individual dots defines the appropriate color and its saturation. In modern printers, apart from standard CMYK inks, other shades which widen the huge color palette are also used.

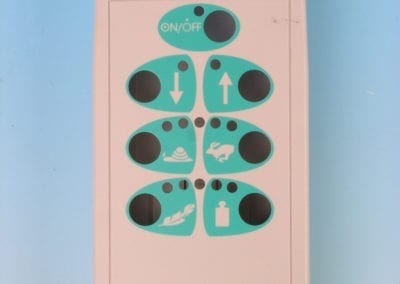

At LC Elektronik we also use a white primer, as well as varnishes and primers. White varnish allows better printing on dark substrates. In addition, the white layer allows you to conquer the base color on dark enclosures. In our practice, printing for example red color on a white foundation works better than printing on the black. And consequently, the red is more pronounced and looks completely different than without a base.

At LC Elektronik we also use a white primer, as well as varnishes and primers. White varnish allows better printing on dark substrates. In addition, the white layer allows you to conquer the base color on dark enclosures. In our practice, printing for example red color on a white foundation works better than printing on the black. And consequently, the red is more pronounced and looks completely different than without a base.

Inks cured with UV radiation

In digital printing technology, LC Elektronik uses inks that are cured by UV radiation, immediately after passing through the print head. Thanks to this, prints are pre-fixed after removing from the machine. For the print to be durable and 100% resistant to scratching, The print needs to rest for a minimum of 12 hours, it is necessary for durable and resistant to scratching.

Why we use direct digital printing?

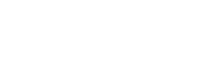

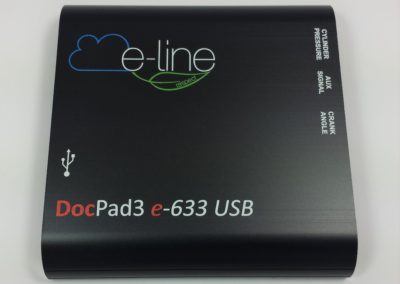

Direct digital printing is most often used for printing on enclosures. This applies to cases made of ABS, polycarbonate as well as cast aluminum and aluminum profiles. Thanks to the use of a wide range of surface preparation technologies before printing, we can print any material.

Digital printing gives great aesthetic possibilities as well as personalizing print in the form of serial numbers, markings or other individual prints. Therefore, it eliminates the additional production of labels and nameplates. Digital printing does not usually require additional production stages, we do not need to expose the film, make dies or sieves, so it is much cheaper than other technologies. Digital printing allows you to create a product with a consistent, modern aesthetics, and what’s more, at a reasonable price.

Conditions and limitations in direct digital printing

- The size of the printed surfaces

Currently, we are able to print enclosures with a height of max. 140 mm. This is due to the clearance that we have in current machines.

- The printable area

Another limitation is printing on slightly curved areas. Namely, we do not print on rounded surfaces because the print quality does not meet our quality standards.