Rubber keypads, thanks to their properties, offer many possibilities for designing electronic devices. So in order to make the right choice with your keypad, it is worth to know the properties and consult the different solutions with technical support before making the order.

How silicone keypads are made?

The rubber keypad is manufactured in the process of high-temperature vulcanization of silicone.

Types of rubber keypads construction

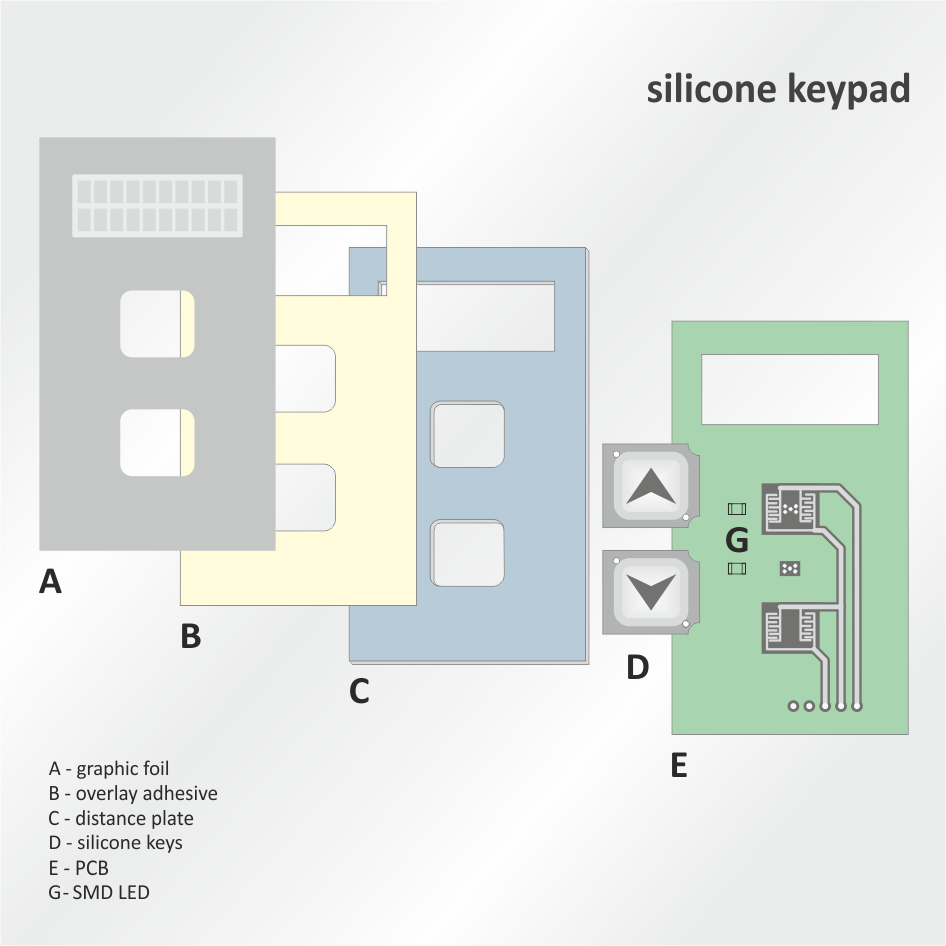

In the construction of silicone keypads we can make a division (get the contact) due to the conductive element.

We distinguish three types of construction:

- A printed conductive paste containing contact areas on the conductive circuit. It is possible to make any shape of the plane that contains the contact.

- A vulcanized conductive element containing contact areas on the conducting circumference. Only standard shapes available.

- A metal plate or switch mounted on a conductive circuit, where the rubber keypad is

a pusher.

Thanks to its properties and processing capabilities, silicone is an excellent material for general use applications.

Furthermore a wide range of silicone and print colors, according to the RAL palette, gives us great opportunities to create a perfectly personalized product.

Additional protection

In the rubber keypad, by surface spraying with PU varnish, an increase in abrasion resistance is obtained. In addition, you can increase the visual qualities of the keypad by pouring epoxy resin drops on the surface.

Backlighting of rubber keypads

It is possible to use a silicone with the properties of transmitting light with a light source placed on the conductive circuit, then we obtain the effect of the entire surface of the silicone lighting. The effect that pictograms only shine we can obtain by surface sputtering of the keypad surface with covering paints and then laser engraving of pictograms.

Advantages of the rubber keypads:

- comfort of use

- greater possibility of differentiation of pressure force and keys travel in comparison with membrane keypads

- easy to keep clean

- resistance to mechanical damage

- durability

- backlighting

- larger packing of keys on the surface compared to a membrane keypad

- relatively low production costs.

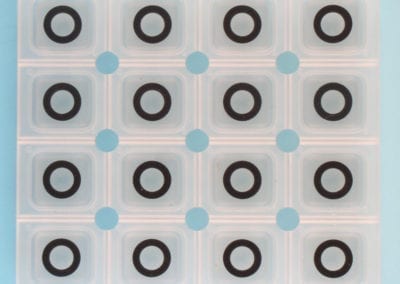

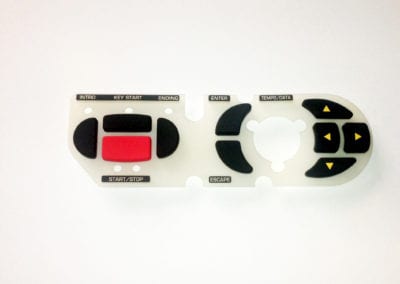

Example constructions of rubber keypads

keypad with silicone cover

silicone keypad

Basic properties of the rubber keypads

| Color | based on the RAL palette, the ability to combine the colors of silicones in the area of the keypad |

| The shape and size of the keypad | any |

| The shape of the contact of conductive carbon resin, preferred size |

|

| Keypad construction |

|

| Key travel (jump), preferred values | 0,8 mm, 1 mm, 1,2 mm, 1,5 mm |

| any, based on the RAL palette the number of printing colors can be any |

|

| Pressure, preferred values | 100 gr 120 gr 150 gr 180 gr 200 gr |

| Key surface finishing |

|

| Vulcanization of keypad components | silicones of different hardness and colors |

| Life cycle | min. 1 million |

| Hardness | 55° +/-5° |

| Surface laser engraving | yes |

| Backlighting of the keypad descriptions | spraying by coating inks on the entire face of the keypad, for use in engraving pictograms |

LC Elektronik offers many solutions. Choose from different technologies and find the best one for yourself

Make your production and modification

with LC Elektronik

Here you can buy professional enclosures for your equipment.

You will adapt your casings to your needs and give them an individual character with us.

Engraving, printing and milling on housings – we will do it for you.

We also design and manufacture keypads, graphic overlays, display windows and front panels.

All in one place with one supplier and manufacturer.

Do not waste time or money, design and manufacture your device

or operator panel in LC Elektronik.

Hallo,

I an looking at manufacturing some components for use in a Flight simulator and I will need to have some rubber keypads made. What is the minimum order of products? How would I supply the files? As dfx/svg/step/stl?

Dear Andrew,

STP files will be the best, but also DXF will be ok. Please contact directly with our technical advisor – Tomasz Kaminski – Tomasz.Kaminski@lcel.com.pl