What are display windows?

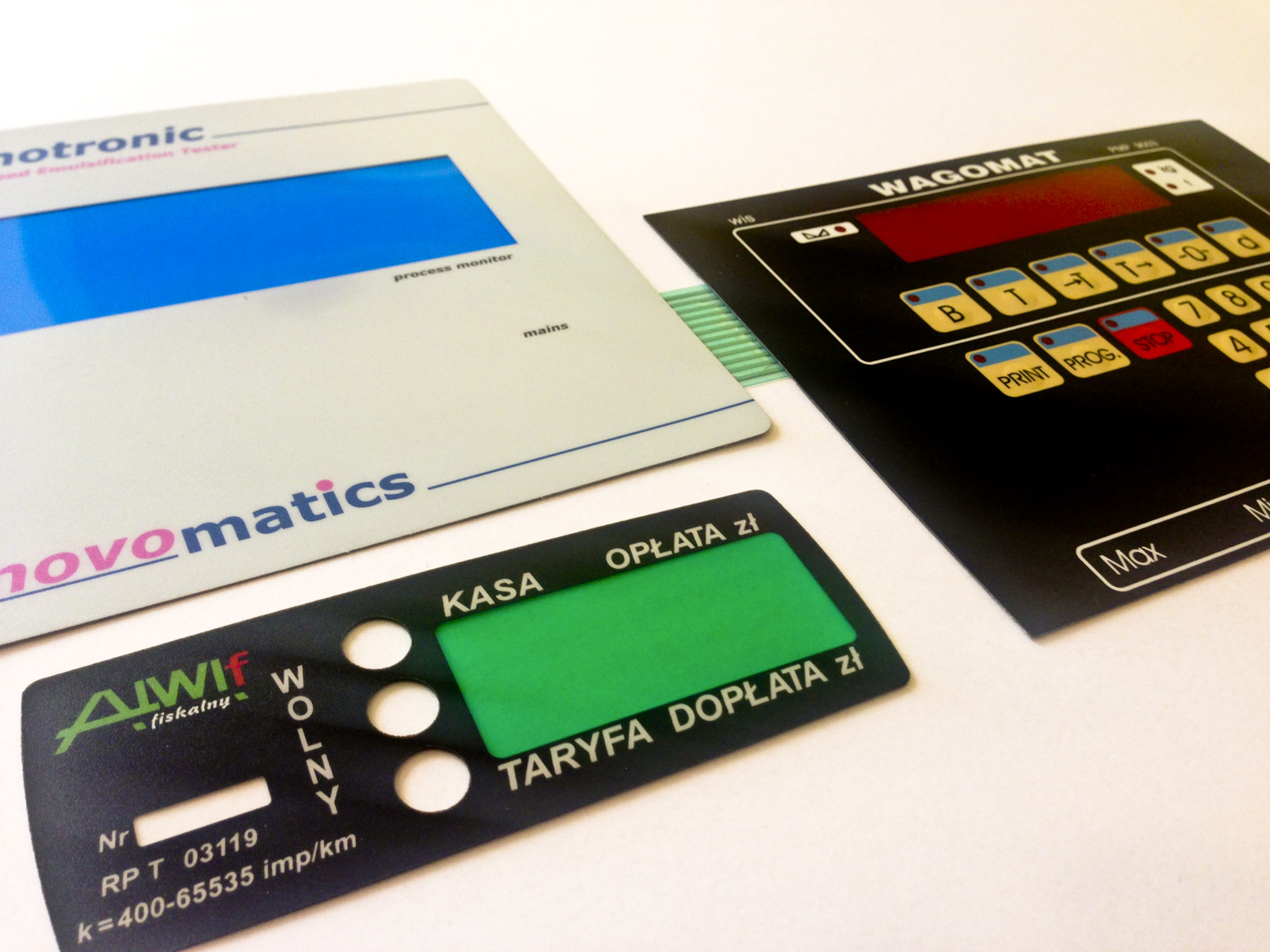

The display window is the basic element of the operator panel. It is used to display the work status and control the operation of the device. The display windows are additional tiles or layers of foils which protect and sometimes change the color of the display area.

Due to the application, the selection of materials is very important. Therefore, the interface should be primarily readable and the displayed view should be clear. What is more, due to the purpose and continuous operation of the panel, the materials from which it is made should be durable and resistant to external factors.

What materials are the display windows made of?

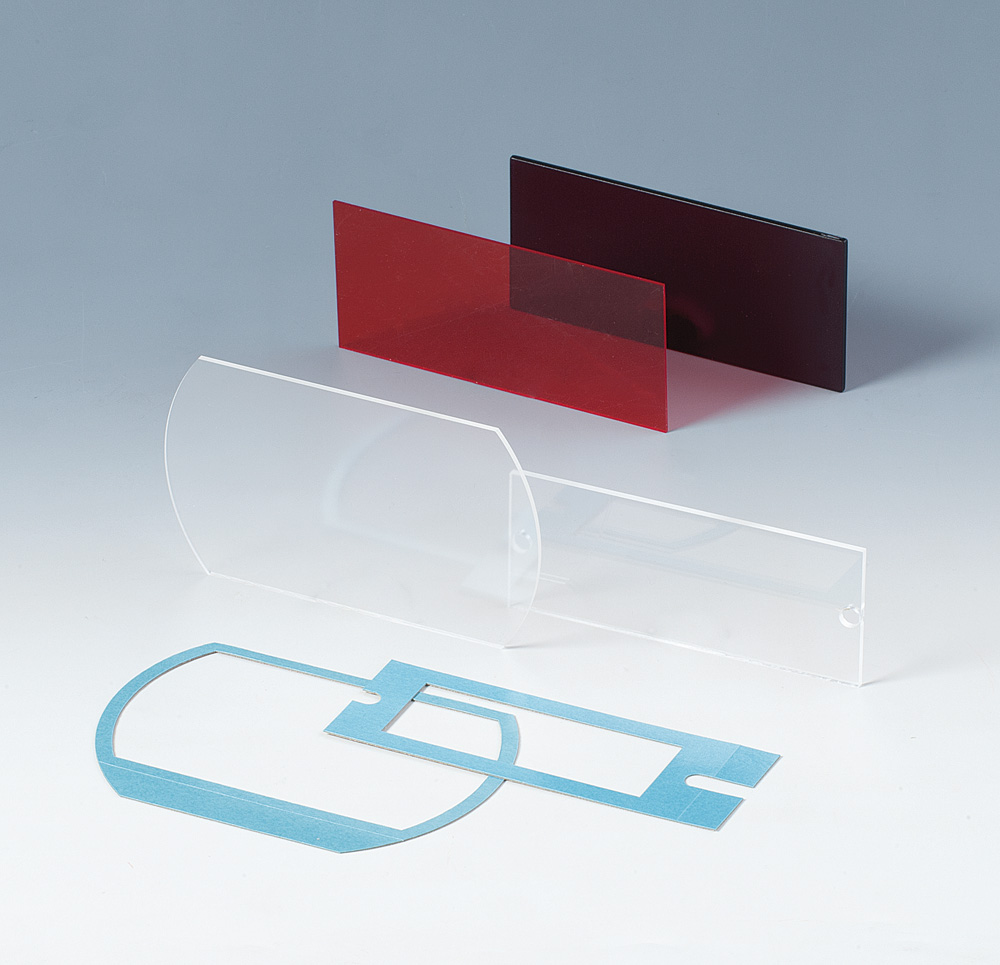

We have a range of materials with different thicknesses – from 0.150 mm to 3 mm. The most popular material from which we make display windows is PMMA with various technical and material specifications. In order to protect the display or the top layer of the keypad from damage, we usually use a window with optically clear PMMA. Thanks to optical bonding technology, we constantly connect the window with the keypad or display. By using our 4 lasers, we precisely cut out the tiles, so we can achieve high cutting accuracy.

Colored optical filters

PMMA is available in many colors so you can easily change the hue of the display and customize it to your requirements. Sometimes the designer is not able to select displays with the same color characteristics, in such a situation the filter is printed on the display window. So in such a simple and relatively not expensive way, you can change the color of your display.

Technical Coatings

The most commonly used materials are also PMMA with various coatings. The offer includes:

- anti-reflective coatings

- hard-coated

- matt.

EMI-RFI protection

Nano print

Another group of materials is PMMA boards with a conductive layer in nano printing technology. Nano print ensures very good shielding against all electromagnetic waves and other disturbances, both peripheral devices and the display’s radiation itself.

Steel mesh

If you need shielding, we offer a solution with a conductive mesh which is placed above the display. The most important is to prevention to additionally not to interfere with the light from the display, so it is necessary to adjust the appropriate angle of cutting the grid.

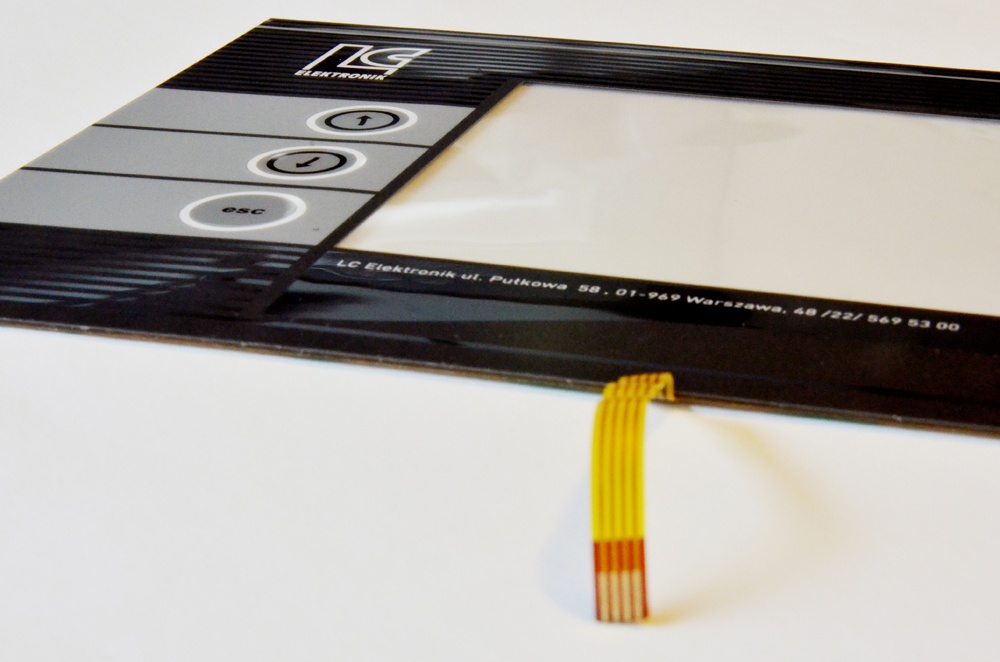

How to avoid Newton Rings in the production of display windows?

You know this problem, when multi-colored rings appear on the display, arising at the point of refraction of the display surface. Nobody likes this, so panel manufacturers strive to eliminate this phenomenon. Responding to these needs LC Elektronik developed two proven – on 100,000 copies – solutions, thanks to which the phenomenon of rings was eliminated or reduced to a minimum

Optical bonding

Firstly, optical bonding, about which you can read more HERE. This technology consists in gluing a plate made, for example, from PMMA to the front of a membrane keypad or a foil front. Optical bonding technology requires a dust-free room and specialized equipment to avoid dust particles and air blisters. It is a very useful method if we want to strengthen the display and keep the best optical values and reduce interference.

Distance fields in display windows

The second method is printing from the inside site the foil front or keypad, small distance plates with a thickness of approx. 0.1 mm and a diameter of approx. 0.2 mm. These dimensions depend on the size of the area itself as well as the shape. Thanks to such small points, the film does not bend so much and Newton’s Ring effect is significantly reduced or completely eliminated.

We know how much reliable operator interface is important for our customers.

That is why we make every effort to ensure to design and manufacturer display windows,

which are functional, durable and tailored to the customer’s needs.

With us you will make a prototype or plan the whole series.