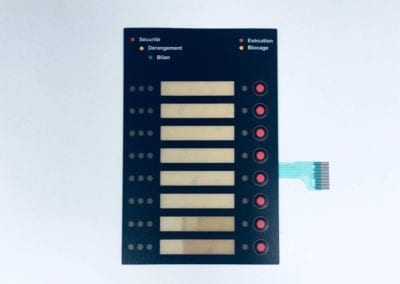

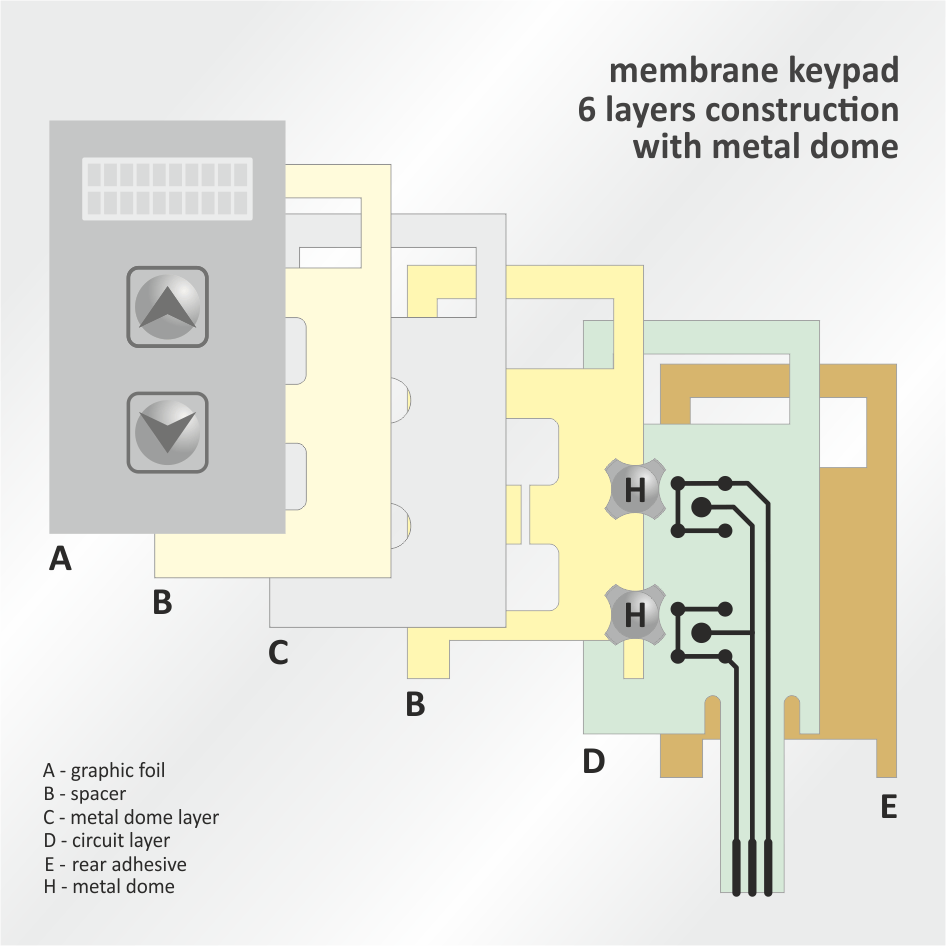

Membrane keypad called also the foil keypad – consisted of many layers of films, with different properties and functions, combined with adhesive overlays.

The basic elements of the membrane keypad

Graphic overlay – is the first layer covering the keypad on the outside. It is responsible not only for protection but also for attractive design. It is printed from the inside. The graphical possibilities are almost limitless here. The film can be made of polycarbonate or polyester. In our practice, polyester films are much more effective, because they are more flexible and resistant to external factors. We recommend them in particular for more demanding and professional applications. The first layer can be subjected to additional processing, e.g. make stamping or print with structural lacquers. Depending on the varnish used, we can give the keypads appropriate texture: glossy, antiglare or hard coated.

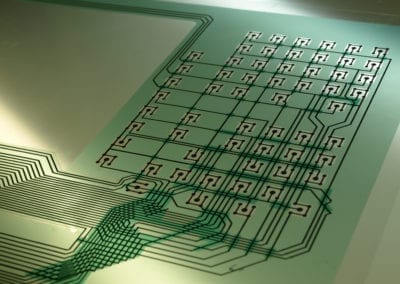

Circuit layer – a key layer for keypad operation is a polyester film, on which the paths and contact pads are printed. The circuit layer can also be stamped to form polyester membranes, i.e. the element which gives the impression of being clicked when pressed,

Spacers and adhesive layer – adhesives which are double-sided self-adhesive polyester films covered with a layer of acrylic adhesive. They are used for gluing different films and circuit layer together, also for the keypad to the enclosure or supporting plate mounting.

Metal domes – specially formed metal switching elements, mounted into a silver circuit. With pressing and “click” they cause short-circuit and switching given function.

- Additional elements may be for example SMD LEDs.

Advantages

– many design possibilities (customization)

– aesthetics

– durability

– resistance to external factors: atmospheric, chemical and mechanical

– low price in large series

– extremely thin construction.

Membrane keypad application

The membrane keypads are widely used in both domestic and industrial devices, e.g. in control and measurement equipment, in control systems as well as in the military, medical and automotive industries.

Design and production technology offers many possibilities and different properties.

Exemplary constructions

flat keypad

spherically embossed keypad

embossed keypad with SMD LED

embossed keypad with laminated window

embossed keypad with a plug in bag for descriptions

embossed keypad with polyester dome

flat embossed keypad with a metal dome

frame embossed keypad with a metal dome

embossed keypad with metal dome and SMD LED

embossed keypad with touch panel

embossed keypad with window`s shielding

spherically embossed keypad with EMI / RFI

Technical information

| Graphic overlay material |

modified, heat stabilized polyester or polycarbonate foils |

| Paths and contact pads material | silver based inks |

| Number, shape, thickness of paths | any |

|

Connection, flexible connecting tail:

|

– Crimpflex connector in pitch 2.54 mm – tail end prepared for ZIF or non-ZIF connector in pitches 2.54, 1.25, 1.00 mm – possibility of extension the tail by DWFC technology |

|

IP |

IP65 (front) |

| UV resistance |

yes * – in moderate conditions of our climate zone * In the conditions of strong UV radiation, we recommend making a prototype |

| Contact resistance |

<0,06 ohm/square – depends on conductive path geometry |

| Operating current | recommended to 20mA |

| Operating voltage | recommended to 24V |

| Power rating | max. 1W |

| Life cycle | min. 1 million activations |

|

Operating temperature range of keypad/nameplate |

embossed: 0°C to +45°C flat: -20°C to +70°C |

|

Storage temperature range of keypad/nameplate |

embossed: -20°C to +45°C flat: -30°C to +70°C |

| Keys |

– flat – pressed – with metal membranes |

| Window shielding | yes |

| Electromagnetic protection of displays | yes |

| Backlighting | LED one-colored and two-colored |

| Holes |

– any number – any shape – out or in a different way |

| Surface finish |

– glossy – antiglare – hard coated |

| Windows for LED elements |

– transparent – colored filters |

Design

| Color | any |

| Shape | any |

|

– screen printing – digital print |

TABLE OF POPULAR REAGENTS WHICH MEMBRANE KEYPADS AND FRONT FOILS SURFACE ARE RESISTANT TO

| REAGENT | POLYESTER | POLYCARBONATE | ||

| 1 hour | 24 hours | 1 hour | 24 hours | |

| Methyl ethyl ketone |

+ |

+ |

||

| Cyclohexanone |

+ |

+ |

||

| Acetone |

+ |

+ |

||

| Ethanol |

+ |

+ | + |

+ |

| Tricloroethanol |

+ |

+ |

||

| Tricloroethylene |

+ |

+ |

||

| Petrol |

+ |

+ | + |

+ |

| Diesel Oil |

+ |

+ | + |

+ |

Thanks to our many years of experience and knowledge, they are constructed in such a way that they ensure trouble-free operation.

All keypads are made in 6W technology, with using 6 layers. This technology and proper chose construction makes our products work for many years, even in tough climatic conditions.

Installation instructions for the membrane keypad

LC Elektronik offers many solutions. Choose from different technologies and find the best one for yourself

Make your production and modification

with LC Elektronik

Here you can buy professional enclosures for your equipment.

You will adapt your casings to your needs and give them an individual character with us.

Engraving, printing and milling on housings – we will do it for you.

We also design and manufacture keypads, graphic overlays, display windows and front panels.

All in one place with one supplier and manufacturer.

Do not waste time or money, design and manufacture your device

or operator panel in LC Elektronik.