Green Electronics: How to Reduce Carbon Footprint and Meet ESG Requirements?

Clients and regulators no longer accept traditional production methods. The answer to these changes could be printed electronics—a technology that reduces CO₂ emissions, lowers material use, and boosts a company’s competitiveness.

Roll-to-Roll vs. Sheet-to-Sheet: Which Method Should You Choose for Your Project?

Choosing the right production technology for electronic components is crucial for final quality, costs, and process efficiency. For engineers, deciding between Roll-to-Roll (R2R) and Sheet-to-Sheet (S2S) methods isn’t just about speed – it also depends on technical limits and material requirements.

Risk Management in Electronics Manufacturing: Five Traps That Can Ruin Your Project

Electronics production is a bit like managing a Formula 1 team – speed, precision, and flexibility decide success. Every project manager knows that even the best-planned project can go wrong because of unexpected problems. Lack of components, design mistakes, wrong materials – all of this can mess up your timeline like an Excel sheet after accidentally deleting a few columns.

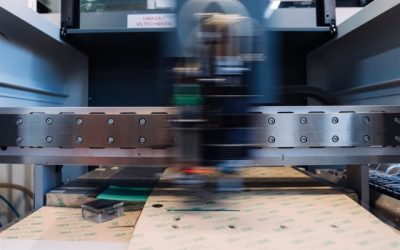

Modified enclosure for the device for IT industry

HOW ARE WE MAKE THIS IN LC ELEKTRONIK? MILLING | PRINTING | SELF-CLINCHING FASTENERS TAKACHI PF SERIES PROJECT SUPERVISOR Paweł CzabakCLIENT MONOLIT IT - a company specializing in integrating IT systems PURPOSES Choosing the right enclosureand...

Modification of enclosures | Milling | Printing | Marking

Modifications and adaptation of catalog enclosuresStandard enclosures are a common choice of electronics manufacturers. However, personalization and adaptation of the enclosures requires to fulfill task of device, not only for the aesthetic and functional reasons but...

Industrial device marking

Industriual engravingThe marking of equipment in industry is standard. Function marking of the keys, punching the serial number, bar code, graphic signs and company logo is so easy. Engraving is one of the most durable and effective methods for marking electronic...

FASTENERS MOUNTING TECHNOLOGY

The PEM® elements self-clinching fasteners Self-clinching fasteners are threaded nuts, studs or stand-offs that are mechanically pressed into metal or plastic, becoming a permanent part of a panel, enclosure or bracket. The common name of these connectors is PEM®,...

Enclosures for IoT systems

Smart enclosures for electronic devices in IoT system IoT technology becomes so popular and easily available, so the market reaction does not surprise. Manufacturers are doing everything to keep up with the trends and needs of customers. They introduce new...

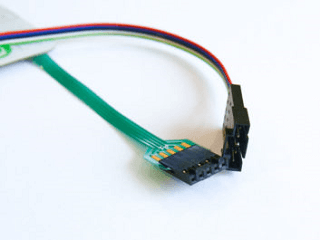

Connectors for keypads – flex connections

Connection of the keypad with control electronics There are many ways to combine the keypads with the control electronics. The choice depends on the materials used, technical conditions and customer expectations. At LC Elektronik we rely on the following proven...

Rigid panels part of front plate

Usually the rigid boards are the basic element of the front panel. Together with the keypad, graphic overlay or display, they form a front panel. Depending on the needs, the boards are equipped with additional fastening elements or spacers. The selection of the...